CRYLINK quartz multistage two-and-a-half wave plates are fabricated from single sheet quartz crystals with relatively thick thicknesses for simple fabrication.When a beam of linearly polarized light incident perpendicularly to a wave plate made of uniaxial crystals, it was decomposed in the wave plate into o – and e-light propagating along the original direction but perpendicular to each other in the vibrational direction, and the corresponding refractive indices were no、ne . Since the two kinds of light have different velocities in the crystal, the amount of phase delay produced after passing through a wave plate of thickness d is δ=(2π/λ)|no -ne |*d. Among |no -ne |*d as the optical path difference, the two-thirds wave plate produced an optical path difference of (2m+1)λ/2, the amount of phase delay δ=(2m+1)π, and m as a non negative integer. The m of the multistage two-thirds wave plate was not 0, and the thickness was determined by the series M.Compared with the zero order two-thirds wave sheet, the light passes through the multistage two-thirds wave sheet with an additional m full wavelength phase delay, which is more sensitive to the wavelength. The CRYLINK’s quartz multistage two-thirds wave plate is commonly used to rotate the polarization direction of linearly polarized light.

Parameter

Basic Parameters

| Design wavelength | 266 nm-1550 nm |

| Product ID | PB03002 |

| Optical cell diameter | 25.4 mm |

| Retardation | mλ+λ/2(m as a positive integer) |

| Coating | V-AR Coating |

| AR Coating | R<0.25%a@ design wavelength (6 ° angle of incidence, one-sided) |

| Optic material | Crystalline Quartz |

| Surface parallelism | <3 arcsec |

| Clear Aperture | >90% CA |

| Retardation tolerance | ±λ/300、±λ/100 |

| Surface quality | 10/5 |

Application

- Polarization direction commonly used for rotary linearly polarized light

Feature

- General thickness, 0.3-1.0 mm

- High injury threshold

- Lower price than zero order wave plates

- Compliance with RoHS

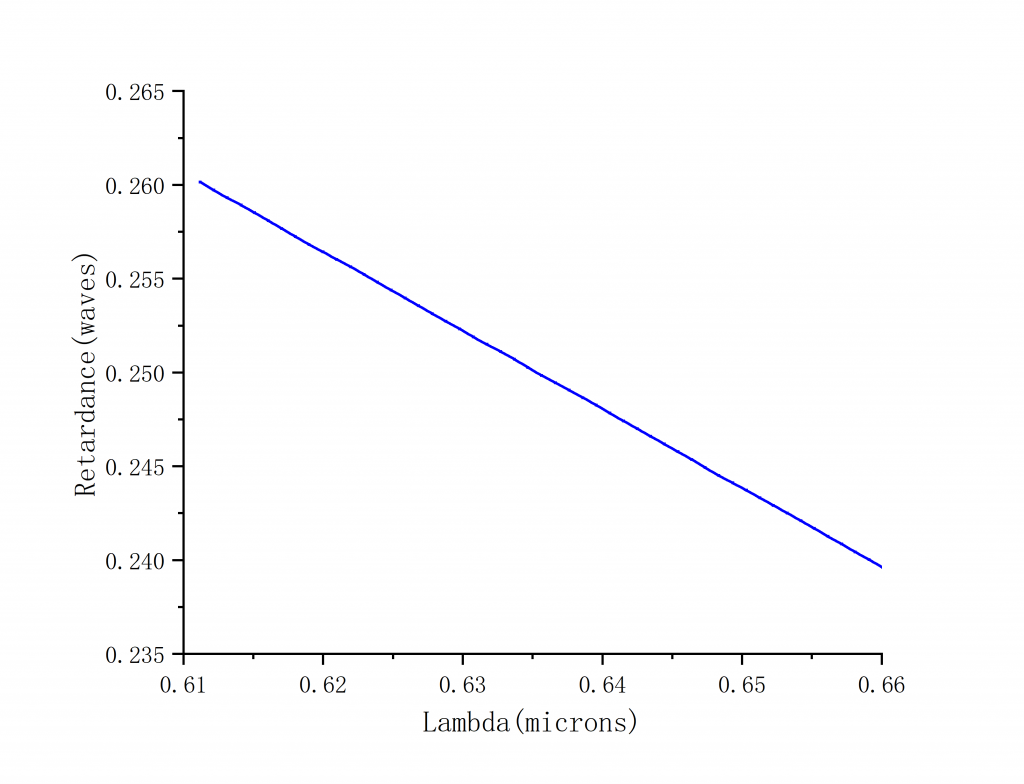

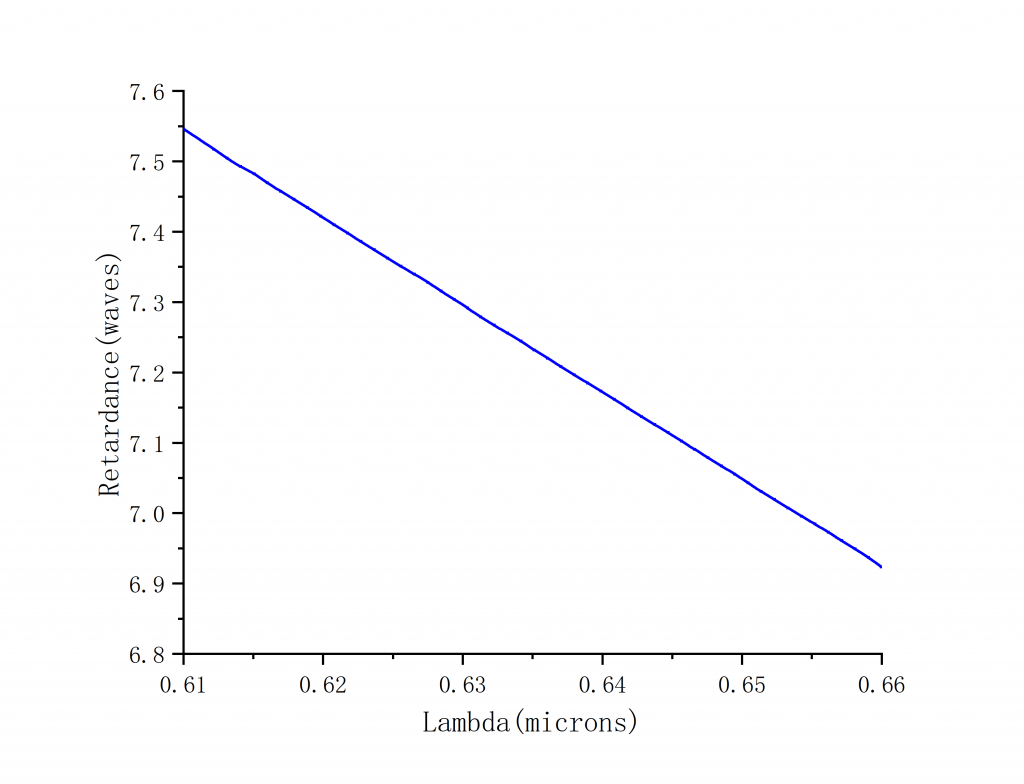

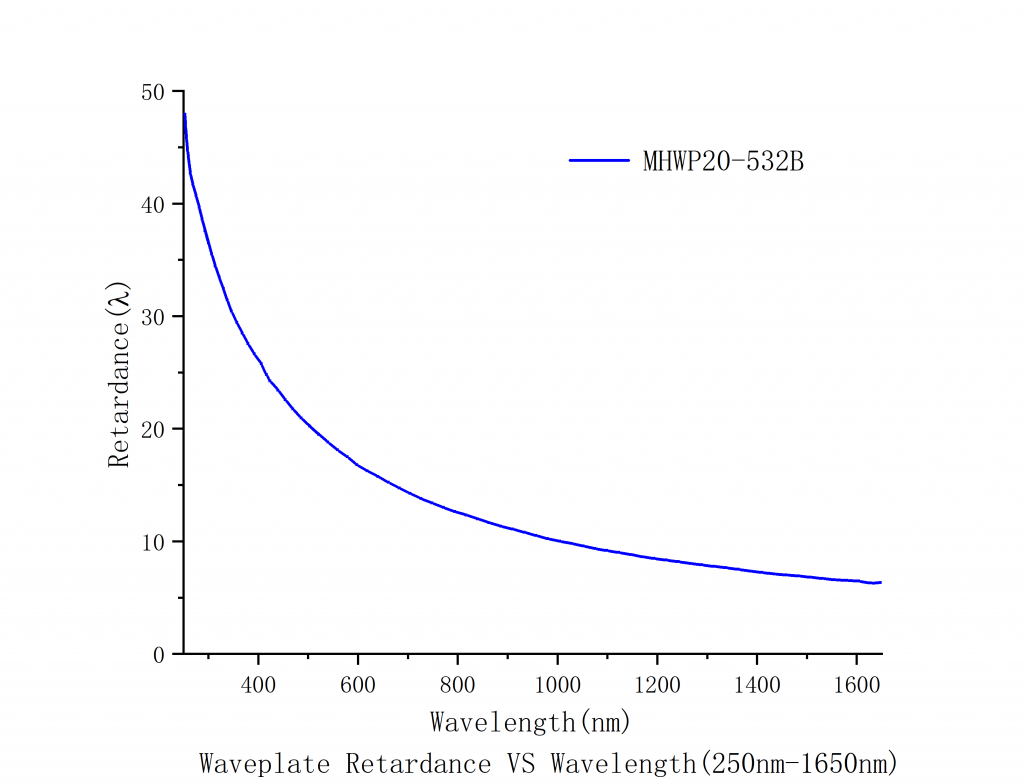

Spectrogram